Introduction

Capture. Understand. Act.

The end-to-end AI vision platform built for your operations.

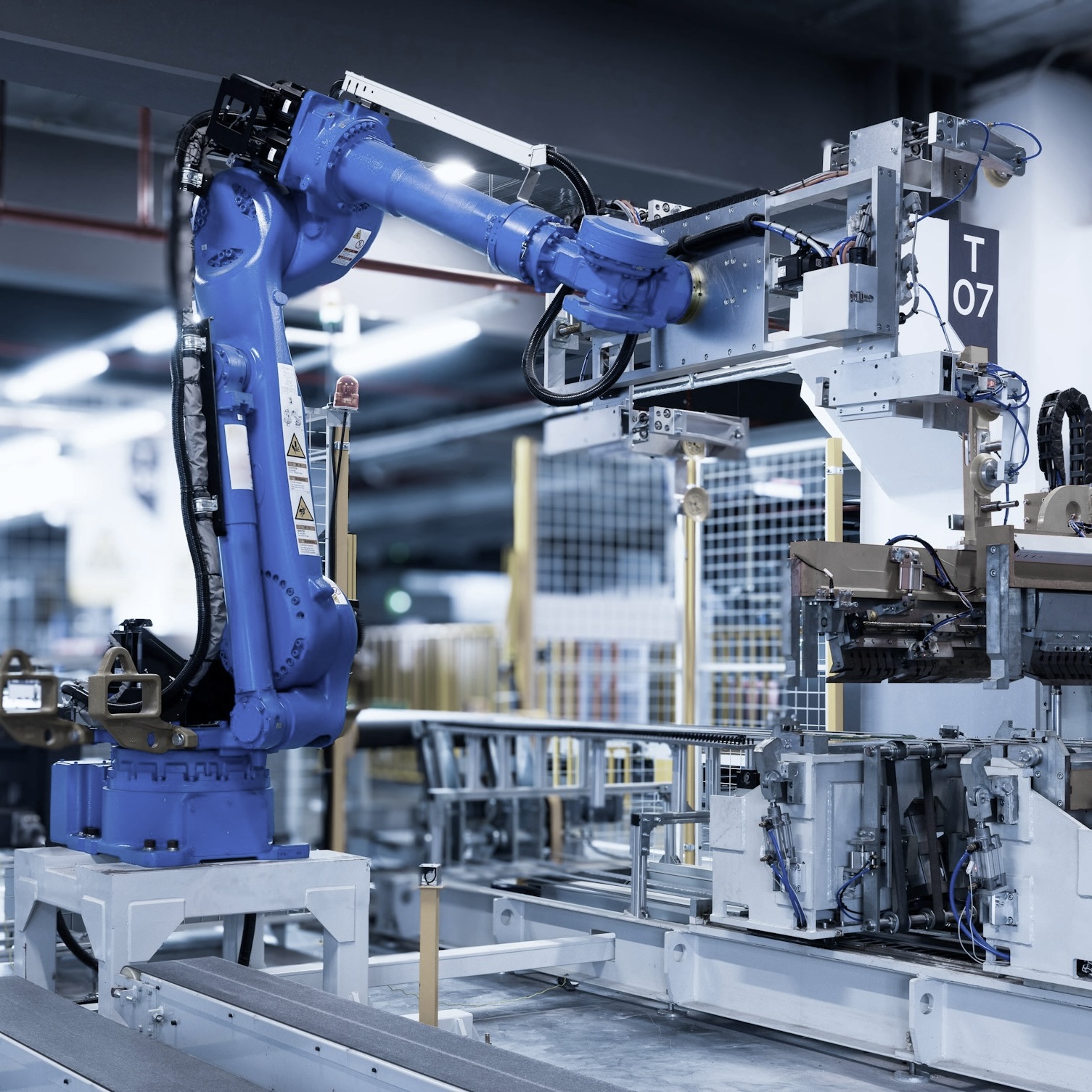

Vision Capture

High-speed, multi-camera capture tailored to your workflow. Controlled lighting, precise calibration, and stable optics ensure consistent quality. Custom-engineered environments built to perform in demanding operations.

AI Engine & Edge Compute

Real-time detection, segmentation, classification, and tracking. Models tuned to your data, edge cases, and operational reality. On-device inference running on robust edge hardware with secure handling.

Dashboard & Insights

A clear results viewer with confidence scoring and rich defect context. Continuous data flows and feedback loops for ongoing optimisation. API-ready outputs that connect detections to your systems and automation.

INDUSTRIES

Automated vision for real operations.

Precision, speed, and reliability for your industry.

OUR PROCESS

How We Work

From concept to deployment, we partner with you at every stage to build vision systems that deliver measurable results.

Discover

We analyze your operations, identify vision opportunities, and define success metrics together.

Validate

We build a proof-of-concept system, test it with your real data, and refine until it works.

Scale

We deploy production-ready systems, integrate with your workflows, and support continuous improvement.

About Us

At AI-Inspect, we specialize in AI-based vision systems to automate inspections of industrial products and company assets.

Our mission is to help customers automate and optimize their production and inspection processes with advanced AI-driven vision systems, delivering more accurate and more consistent qualitative data.

Our multidisciplinary engineering team — with a strong background in aerospace engineering, AI, and machine vision — designs and integrates complete vision systems tailored to customers' workflows, including standalone indoor/outdoor inspection systems and modules for existing production lines.

With more than 30 years of experience in designing, integrating, and realizing complex technical systems, we work with top-class machine vision experts and hardware partners to deliver tailored solutions. At the core of every system is our AI software, using state-of-the-art technology to identify and analyze anomalies and deviations with high accuracy and reliability.

Our Expertise

- 30+ years of experience designing complex technical systems

- Proven track record in aerospace-grade engineering

- Full-stack capabilities: optics, hardware, AI, and system integration

- Trusted partnerships with leading machine vision & hardware suppliers

- State-of-the-art AI models for anomaly detection and defect analysis

Our Vision in Action

Mission-critical vision systems deployed in real-world environments.

Automated Vehicle Inspection

High-accuracy automated inspection system engineered for operational automotive logistics environments.

Wind Turbine Blade Inspection

AI-powered detection of surface defects in challenging renewable energy environments.

Core Capabilities

Engineered for mission-critical vision systems operating in real-world environments.

Anomaly Detection

Detect unexpected defects and deviations — even in high-noise, fast-moving environments.

Controlled Environments Engineering

Aerospace-grade design of lighting, stability, and vision-critical conditions.

Virtual Prototyping & Simulation

Digital twins accelerate design, validation, and deployment.

Object Segmentation

Pixel-accurate surface masks for panels, components, and structural regions.

Multi-Object Tracking

Tracks multiple moving objects in real time with persistent identity assignment.

High-Speed Vision

Real-time processing of high-FPS, multi-camera imaging pipelines.